PRODUCTION FACILITY

We have a state-of-the-art production facility with AHU for complete control of humidity and temperature and world-class infrastructure and impeccably controlled working conditions with extensive quality control to ensure the accuracy and reliability of the equipment.

Our Technology

WAHREN has invested in European-based technology for very high precision quality. Solvent-based lamination is the key process in the manufacturing of Cold Form pharmaceutical packaging film. A world-class machine ensures the highest precision, optimum quality, and consistency.

A six colour roto gravure machine is installed for desired printing of brand names and reproduction of graphics.

WAHREN has invested KAMPH TECHNOLOGY, KAMPH’s efficient and effective solutions with reliable technology for slitting aluminium foils in our converting process.as specialists for slitting all types of foils,

Automated finished roll removal

Precision & Perfection

Conveyor belts/transport carts

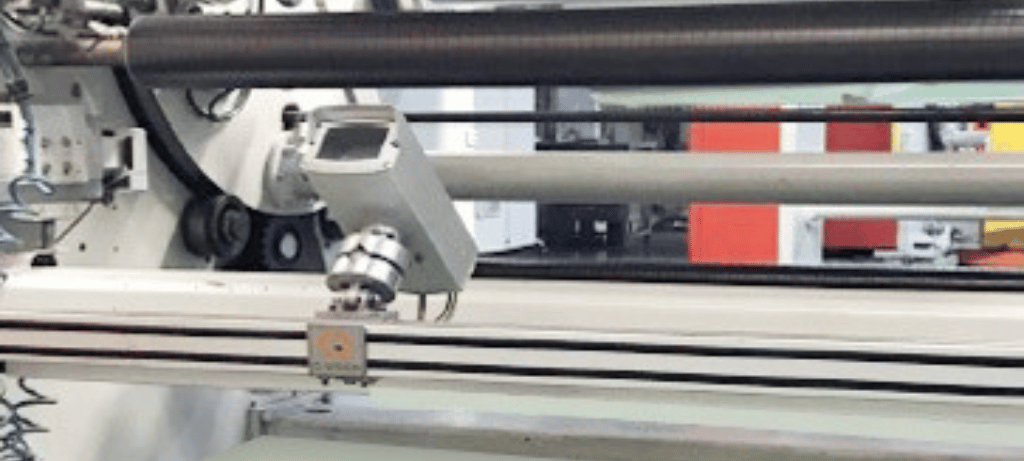

ONLINE OPTICAL FLAW INSPECTION SYSTEM

Leader in online inspection and detection technology, FUTEC from Japan ensures defects, including Fish eyes, foreign matter, and Pin-holes are detected and removed from the film for the highest quality and zero-defect final product.

Analytical Testing

WAHREN has in-house testing laboratories to execute all necessary tests like tensile testing equipment, bond strength testing equipment, heat sealing testing equipment, GSM tester, Micron meter, FTIR test, Forming & Sealing, etc.

Our technical and design recommendations result in deep knowledge not only about material sciences in the lab but also about consumer trends research in the market.